Evaporative Cooler

The way environment is deteriorating, it is the need of the day to conserve energy, save forests for the good health of living human and his progeny.

Maintaining the comfortable temperature for living is the need of this era for human being. In the hot regions Air Conditioners are used to keep the living area cool. But Air Conditioners consumes

tremendous electrical energy and so it is one of the cause environment is being harmed. In above contest use of evaporative Air Coolers for cooling is environment friendly, saves lot of electrical

energy and also supports to run the Air Cooler economically.

Use of paper based cooling pads in manufacturing of evaporative coolers is the latest trend in India and around the world. Quality of the evaporative cooling pads depends upon a paper resin coated

on it. The paper needs to have excellent water absorbing properties to attain lowest cooling temperature and the same time it needs to be strong and have extended life which, depends upon

the resin used for coating on paper.

The use of the virgin paper is against the norms of the “SAVE FOREST” policy. Because wood is whole raw material to produce paper. But unfortunately paper is the major part of the evaporative cooling pad.

The Ultracool knows its responsibility towards saving environment. Ultracool sourced the supplier from the Europe where laws for saving forest are strictly adopted. Ultracool import the paper from

the manufacturer who is the number one supplier of the craft paper for cooling pads. The paper is produced from sawdust pulp and care-fully selected Recycled Fiber (RCF). They provide the

customer with both excellent quality and a high respect for nature. This paper is FSC (Forest Stewardship Council) mixed certified which ensures that products come from well managed forests

that provide environmental, social and economic benefits.

Like paper UltraCool procures other raw materials i.e. resin, glue and colours also from the manufactures from Europe where environmental norms are stringent and material is well accepted

worldwide.

PROCESS OF MANUFACTURING UltraCool cooling pads-

Single sheets of fluted cellulose virgin Kraft paper are impregnated and treated to provide both longevity and efficient wetting. The sheets are adhered together to form a block and

Ultracool pads are cut from the blocks to meet size specifications. Thermal-setting resins are used to strengthen the paper and achieve water resistance. The resin impregnation and cure

creates a rigid paper product that is self-supporting and water-resistant

Available in custom flute angles and sizes

Available in custom flute angles and sizes

Ultracool evaporative pads are produced using

Ultracool evaporative pads are produced using

Most sophisticated curing process

Most sophisticated curing process

Ultracool owes to it’s customer to offer pads produced using latest and Advanced technology by its team of highly qualified and experienced technologist.

Ultracool owes to it’s customer to offer pads produced using latest and Advanced technology by its team of highly qualified and experienced technologist.

Ultracool pads are environment friendly

Ultracool pads are environment friendly

Ultracool has obtained all quality certifications

Ultracool has obtained all quality certifications

The end product is Strongest and heaviest pads available in India

The end product is Strongest and heaviest pads available in India

Made from environment friendly and heaviest craft paper.

Made from environment friendly and heaviest craft paper.

High resin content

High resin content

High Tensil, Dry & Wet crush strength

High Tensil, Dry & Wet crush strength

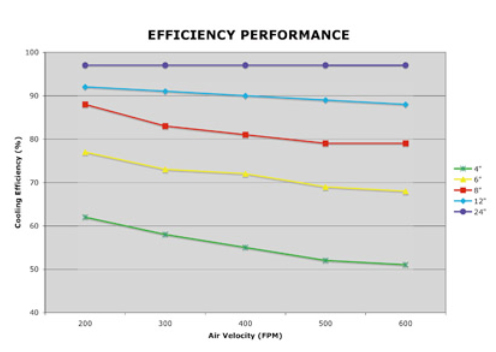

Results of Ultracool pad performance tests:

1. High Energy saver

2. Generate controlled humidity in dry areas which helps to maintains soft skin.

3. Environment friendly

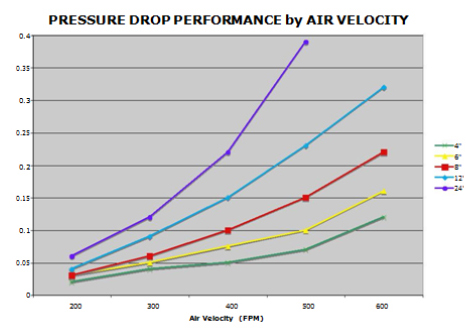

The key in achieving the best performance from an evaporative cooling system is maximizing the amount of air that comes into contact with the cooling pad surface area. Evaporative cooling pads typically produce the most efficient evaporative cooling when they are designed to provide the maximum interaction possible between air and water.

A properly designed and maintained pad-and- fan evaporative cooling system will effec-tively cool ventilation air without wetting a room and its contents. Proper design supplies: 1) water impartially over and through the pad area and 2) the desired air flow through the room. Good maintenance practices preserve the pad and keep the water delivery system in proper working condition.

Single sheets of fluted cellulose virgin Kraft paper are impregnated and treated to provide both longevity and efficient wetting. The sheets are adhered together to form a block and KÜÜL® pads are cut from the blocks to meet size specifications. Thermal-setting resins are used to strengthen the paper and achieve water resistance. The resin impregnation and cure creates a rigid paper product that is self-supporting and water-resistant

Applications